Midwest Clock Repair

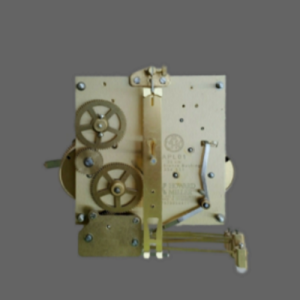

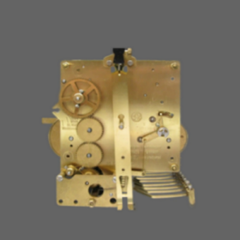

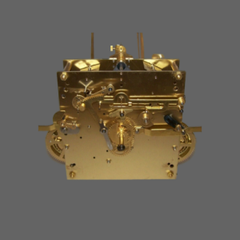

Kieninger Repair / Rebuild Service For The Kieninger APL Westminster Chime Clock Movement

This Rebuild Service Is For The Kieninger APL Pendulum Westminster Chime Clock Movement. (Like The One Pictured)

Please Note: This Is A Clock Repair Service For You To Send Me Your Clock Movement To Be Rebuilt And Then Returned To You.

Don't Replace Your Original Clock Movement With A New One. Have Your Clock Movement Rebuild And Keep Your Clock Original.

Please Read My -Frequently Asked Questions- Page Or Contact Me With Any Questions You May Have.

Don't See Your Clock Movement Listed?

Send me a picture of your clock movement. I will either send you a quote or direct you to the correct rebuild service for your clock movement.

The Listed Price Of $295.00 Includes The Following:

Any bushings the clock movement needs.

This clock movement will receive at least 18+ bushings.

Cleaning and oiling the clock movement.

Cleaning and oiling the mainsprings.

Three year warranty on bushings and labor.

Return shipping is included in the price.

Payment Options Include; Credit Card Or Check. (Please Make Check Payable To -Brian Scobee-)

Other Possible Repair Issues Not Included In The Price:

Damaged Or Broken Parts Such As; Teeth, Pinions, Pivots, Springs, etc. Excessively Rusty Or Tarnished Parts. Any Parts That Are Missing.

When I Receive Your Clock Movement:

I will inspect it for any extra repair issues such as those listed above. If any of these issues are found, I will contact you with an explanation and a price adjustment before proceeding with the rebuild. If you find that the price adjustment is not agreeable, I will return your clock movement to you and issue you a refund, minus the cost of return shipping.

Please Read My -Frequently Asked Questions- Page For Current Turnaround Time.

Packing Instructions:

Please Follow The Packing Instructions To Ensure That Your Clock Movement Arrives Safe And Undamaged. Please Remove The Hands, The Pendulum, The Pendulum Leader, And The Suspension Spring And Wrap Them Separately. Please Wrap Your Clock Movement With Several Layers Of Bubble Wrap. Place Your Clock Movement In A Box, With The Center Shaft Facing Up. The Box Should Be Large Enough So That Your Clock Movement Is Completely Surrounded With Tightly Packed Packing Peanuts. A 12"x 12"x 12" (L x W x H) Shipping Box From Your Local Office Or Shipping Supply Store Should Be Sufficient For This Type Of Clock Movement - Depending On The Size Of The Pendulum.

Please Be Sure To Include - The Hands, The Suspension Spring, The Pendulum Leader, And The Pendulum Along With The Clock Movement.

Please contact me if you require assistance removing or reinstalling your clock movement from its case. We can arrange a time to discuss it over the phone.

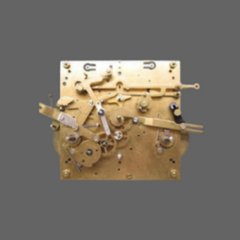

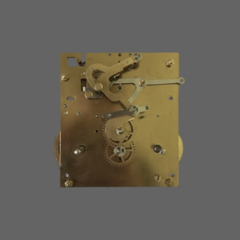

How The Clock Movement Wears:

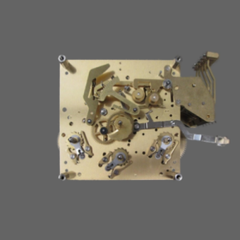

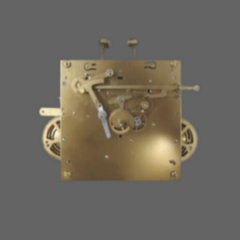

This Kieninger Clock Movement is made up of 2 brass plates with 3 mainsprings and 15 gears in-between them. Each gear shaft has two pivots, one at each end, that ride in a hole in each of the plates. As the movement runs, the pressure from the mainspring turns the first gear in one direction, that gear turns the next gear in the opposite direction, and so on. Whichever direction the pressure presses the gear to run the clock, the pivot holes in the plates will wear in that direction. The more the holes wear, the more the gears drag as they move out of alignment, and the more power the movement needs to continue running. Eventually the movement wears to the point where the mainsprings cannot supply enough power to run the clock. At this point the movement will need to be rebuilt.

How The Clock Movement Is Rebuilt:

First the clock movement is completely disassembled and ran through the cleaner. Next, all the worn pivot holes are realigned and then drilled out to the proper size of the bushing it is to receive. The bushings are then pressed into the holes and touched up with a bushing reamer, as needed, to provide adequate clearance for the pivots. (I use only high quality KWM bronze bushings) The mainsprings are cleaned and oiled and reinstalled. The movement is then oiled, reassembled, and thoroughly tested.